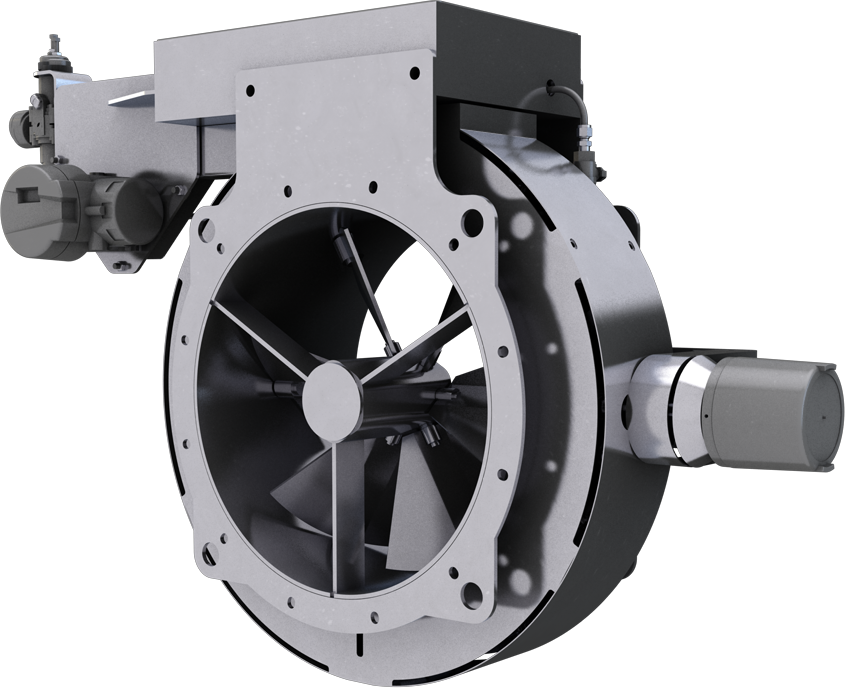

Radial inlet vane controllers consists of a number of segmented shaped blades enclosed in a circular casing.

Blades are pivoted along its axis of symmetry and linked in such a way that all blades maintain an identical angle to the axis of the controller.

This imparts a variable amount of rotation to air stream by creating a vortex on the fan inlet in the same direction as the direction of rotation of the fan. The relative rotational speed of the air at the inlet is the fan speed less the swirl speed, and the fan performs as though it has been slowed down. However, as the device closes, it starts to choke the mass flow.

There are, therefore, two components to control this type of device. At near full open, the control is swirl with little reducing in fan efficiency. At near closed, the control is flow restriction. At any point between, flow is by a combination of this effect.

Speak to the experts

Call today to book a meeting with our engineers

If the device is configured to impart contra rotating swirl, the fan will perform as though the speed has been increased and will give higher volume and pressure. To do this, however, will require increased power, which might overload the motor. The effect can sometimes be used to advantage if a small increase in performance is required, and the installed motor has sufficient power.

This proven product is the result of 25 years of development during which time many thousand units have been installed all over the world. The success of the product is due to good aerodynamics, sound engineering the Badger Damper variable geometry linkage with its facility for site adjustment.

The blades have minimum cross section consistent with adequate strength for the duty required. This results in a high ratio of free are to inlet area. There are no bends, changes of shape or irregularities to induce undue turbulence. Together, these feature result in low pressure loss in the wide-open position (typically 0.15 Vp). Noise generation is also minimised.

Its normal application is therefore the regulation of centrifugal fans although it has proved useful in many other applications requiring shut off to a circular duct. They have been widely used in the glass tempering industries and wind tunnels.

IVC Power Saving Benefits

Click below to learn more about how Inlet Vane Controllers can save you power, energy and costs.