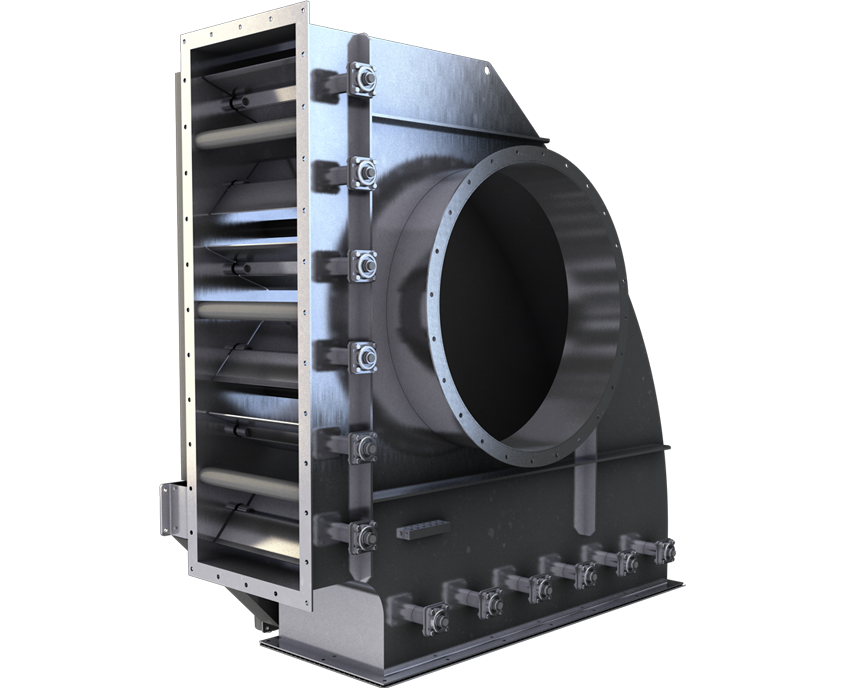

Louvre Dampers Explained

In Essence, Louvre Dampers consist of multiple blades that are linked together to achieve flow control within a small duct section.

Did You Know?...

Badger Damper have developed a blade formed longitudinally for rigidity but represents a very small face area to the flow. The free area is often better than 95%. The Badger Damper Blade is a configuration which has been developed and proven over the last 25 years.

The Badger blade creates minimum noise generation with the blade design achieving a very much higher free ratio than an aerofoil blade, resulting in a lower pressure drop in the open position.

Speak to the experts

Call today to book a meeting with our engineers

Aerofoil section blades suffer from a velocity increase of 20% with consequent changes of static pressure.

These units feature large diameter shaft which are welded to the blades. There is therefore no possibility of the blades becoming detached. Our operating levers utilise our special key design to guarantee linkage alignment and long life.

The shafts turn in bushes or bearings depending upon the application and customer requirements. In many applications they can be considered zero maintenance.

Blade motion can either be parallel (all blades rotate in the same direction) or opposed (alternating contra rotation) as required by the application.

Any weldable material may be specified for construction. Badger damper regularly supply units in stainless steel, or with stainless steel blades in a mild steel case which has been hot dip galvanized after fabrication.

Our unique shaft and operating lever connection gives total security.

Actuation of Louvre Dampers

A full range of operators is available. Manual controls employ either a lever & locking quadrant or a lead screw type mechanism driven by a handwheel.

For power operation we can supply electric, pneumatic, or electrohydraulic with all types of instrumentation including positioners, position re-transmitters and switches. Please contact us for more details.

These can be supplied within high temperature applications.

Discover The Types of Lourve Dampers

Click to learn more about the different types of Louvre Dampers that we're able to manufacture.