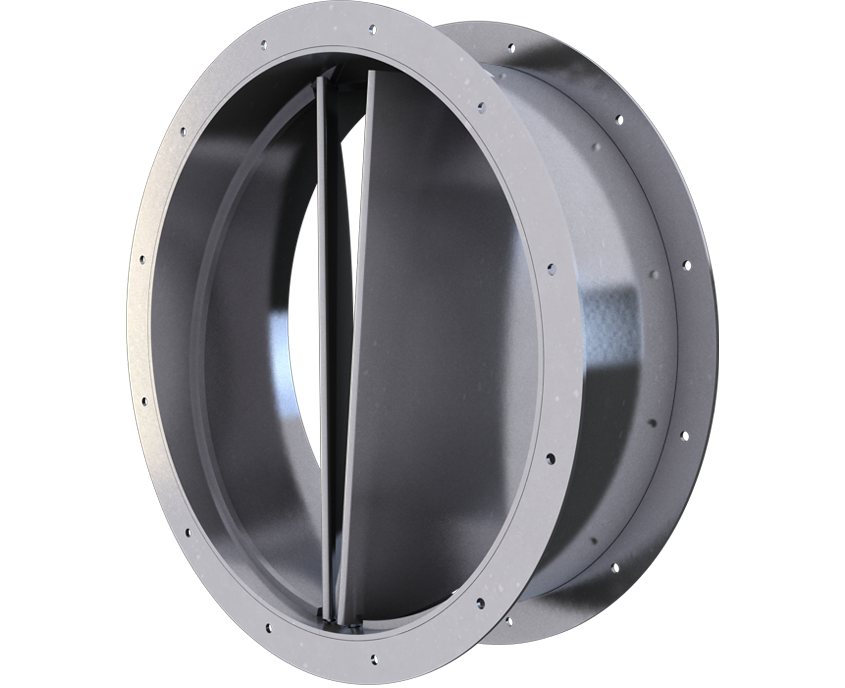

Sometimes known as back draught dampers, this type of equipment is designed to prevent reverse flow in a system.

The objective may be to stop the wind blowing back down the ducting if the fans are off, or it may be to save air from being lost back past a stationery fan in those systems which have run and standby fans.

Again, we place great stress on the design of our blades. This type of device relies on the flow of air to lift the blades and hold them open. The force required must come from somewhere and manifests itself as a pressure drop across the damper which has to be paid for in terms of power absorbed by the fan.

Our blade is effectively under-cambered like the wing section of a high-performance glider. Thus, unlike the simple plate blade often employed, our blade lifts into position rather than being blasted open, with consequent lower pressure drop. The rounded leading edge enhances performance and ensures quiet operation.

Speak to the experts

Call today to book a meeting with our engineers

As with all devices of this type, lowest possible blade weight is essential, dictating the use of light gauge material. The leading-edge box on our design provides the stiffness and strength to resist the loads distributed over the blades in a reverse flow situation.

This type of damper is available in the same range of materials as our Louvre Dampers and can also be designed for blade spans up to 2 metres, depending on maximum possible reverse pressure.

They are designed to suit vertical or horizontal flows. With the blades suitably constructed and engineered to fall back under their own weight.

We produce dampers that have zero leakage and are suitable for use within Atex critical environments. Dampers can be pressure tested to give the customer complete assurance they are fit for purpose.